Gas Station Workwear Reflective Strips: 3M vs. Regular Material Safety

I always choose 3M reflective strips for gas station workwear because they provide better protection in high-risk environments. Visibility workwear plays a huge role in safety on the job, especially when I work late or during bad weather. High-visibility safety apparel helps prevent accidents by making me stand out. Regular reflective material may not meet the same safety standards or last as long, so I trust 3M for reliable workwear and lasting safety.

Key Takeaways

Choose 3M reflective strips for superior visibility and safety in low-light conditions.

Reflective strips enhance safety by making workers more visible to drivers and equipment operators.

Regular reflective materials may not meet safety standards and can fade over time, reducing effectiveness.

Always check for ANSI/ISEA 107 compliance on safety vests to ensure adequate protection.

Proper maintenance, like washing in cold water, extends the life of reflective strips and keeps them effective.

Consider comfort and flexibility when selecting workwear; 3M materials provide a better fit for long shifts.

Investing in high-quality reflective gear can prevent accidents and improve overall workplace safety.

Regularly inspect your vest for wear and replace it if reflective strips show signs of fading or damage.

Reflective Strips

What Are Reflective Strips

When I put on my high visibility clothing, I always check the reflective strips first. These strips are special sections on my workwear that shine brightly when light hits them. Their main function is to make me stand out, especially in places where cars or machinery move quickly. I rely on reflective strips to keep me safe during my shifts.

Reflective strips are essential for reflective safety vests, playing a crucial role in keeping the wearer visible and safe in all kinds of conditions.

Reflective strips use advanced technology. Manufacturers often make them from glass beads or micro-prismatic tape. These materials bounce light back toward its source, which means drivers see me from a distance. I feel more confident working at night or in foggy weather because my reflective tape works even when visibility drops.

Reflective strips are made from materials like glass beads or micro-prismatic tape.

They reflect light back to its source, increasing visibility.

Particularly effective in low-light conditions, such as fog or heavy rain.

Why Reflective Strips Matter

I have learned that visibility can mean the difference between safety and danger. Reflective strips in high visibility apparel alert drivers and equipment operators to my presence. This is especially important at gas stations, where vehicles move in and out constantly. When I wear high visibility clothing with reflective strips, I know I am easier to spot in hazardous conditions.

Reflective strips enhance visibility in low-light situations. Night shifts and bad weather make it hard for others to see me. The reflective materials on my vest ensure I am visible from a distance. I have seen how reflective tape can prevent accidents by giving drivers more time to react. I always recommend high visibility apparel with quality reflective strips for anyone working in risky environments.

Types of Reflective Materials

I often get questions about the difference between fluorescent and reflective materials. Both play a role in safety, but they work in different ways. Fluorescent materials use daylight to glow, making them perfect for outdoor daytime jobs. Reflective materials shine when artificial light, like headlights, hits them. This makes them ideal for nighttime or low-light settings.

Aspect | Fluorescent Materials | Reflective Materials |

|---|---|---|

Light Source | Require daylight (UV light) to glow. | Require artificial light (headlights) to shine. |

Daytime Visibility | Effective in contrast; bright colors stand out. | Essentially invisible in bright daylight. |

Nighttime Visibility | Ineffective; appear dark in darkness. | Very bright under headlights at night. |

Applications | Best for outdoor daytime jobs. | Best for night or low-light settings. |

I choose reflective materials for my workwear because I often work at night. I want to make sure I am visible no matter the lighting conditions. Reflective tape gives me confidence that I am protected, whether I am working in daylight or darkness.

3M Reflective Material

3M Technology

When I choose workwear, I look for advanced retroreflective technology. 3M stands out because it uses proprietary methods to make its retroreflective tape. I have learned that 3M combines microscopic glass beads and prismatic lenses in its reflective materials. These features help return light directly to its source, making me visible from far away. I rely on 3M’s Home Wash and Industrial Wash product lines because they keep their retroreflective properties even after many washes. For hazardous environments, I trust 3M’s flame-resistant (FR) options. The company bonds its retroreflective tape with a special polymer layer, which adds durability and keeps the tape working in tough conditions.

Product Line | Description |

|---|---|

Home Wash | Designed for home laundering, ensuring durability and performance. |

Industrial Wash | Suitable for industrial laundering processes, maintaining reflective properties after multiple washes. |

FR | Flame-resistant materials that provide safety in hazardous environments. |

Beaded Technology | Utilizes microscopic glass beads to reflect light, enhancing visibility. |

Prismatic Technology | Features prismatic lenses that return light to the source, improving nighttime visibility. |

I see 3M’s commitment to innovation in its use of wide-angle, exposed retroreflective lenses. These lenses help me stay visible from different directions. The company also uses smart textiles and LED technologies in some products, which push visibility even further. I feel confident knowing my vest uses the latest retroreflective tape technology.

3M Visibility

Visibility is the most important factor for me when working at a gas station. I need to stand out in low-light and nighttime conditions. 3M’s retroreflective tape makes me highly visible under headlights and streetlights. The prismatic technology in 3M’s reflective materials returns light to drivers, so they see me quickly. I have noticed that 3M’s retroreflective tape works better than regular options, especially in fog or rain. The light dispersion is even, which means I do not have dark spots on my vest.

I also appreciate that 3M continues to improve its retroreflective technology. I have seen new products with microprismatic features and even glow-in-the-dark properties. These innovations help me stay safe in total darkness. I trust 3M because its retroreflective tape meets strict safety standards and keeps me visible in all conditions.

3M Durability

Durability matters to me because I wash my workwear often. 3M’s reflective materials hold up well after repeated laundering. I use both Home Wash and Industrial Wash versions, and both keep their retroreflective qualities. The special polymer layer protects the retroreflective tape from wear and tear. I have worn vests with 3M tape for months, and the reflective strips still shine brightly.

I also think about the environment. I know that manufacturing and disposing of reflective materials, including 3M’s, can raise environmental concerns. These products come from non-renewable resources and are not easy to recycle. However, I appreciate that 3M has a Pollution Prevention Pays (3P) program. This program has prevented billions of pounds of pollutants by reformulating products and modifying processes. I feel better choosing 3M because the company tries to reduce its environmental impact.

Tip: Always check the care label on your vest. Proper washing helps maintain the retroreflective tape and keeps you safe longer.

3M Comfort

Comfort matters to me every time I put on my gas station workwear. I spend long hours on my feet, moving between pumps and helping customers. I need gear that feels good and does not distract me from my job. I have found that 3M retroreflective materials make a big difference in how comfortable my vest feels throughout my shift.

When I wear a vest with 3M retroreflective tape, I notice the fabric stays flexible. The tape does not feel stiff or scratchy against my skin. I can move my arms freely, bend down, and reach overhead without feeling restricted. I appreciate that 3M designs its retroreflective strips to work with the fabric, not against it. The tape bends and stretches with my movements, which helps me stay focused on safety and service.

Breathability is another important factor for me. Gas stations get hot in the summer and cold in the winter. I need workwear that keeps me comfortable in all kinds of weather. 3M retroreflective tape does not trap heat or moisture. My vest stays cool and dry, even when I work outside for hours. I do not have to worry about sweat building up under the tape, which makes my shift much easier.

Tip: I always look for vests with mesh panels and lightweight retroreflective tape. These features help me stay cool and comfortable, especially during busy shifts.

I also pay attention to how the retroreflective tape feels after many washes. Some regular tapes get rough or peel off over time. 3M retroreflective strips stay smooth and securely attached to my vest. I do not feel any irritation, even after months of use. The tape does not crack or lose its flexibility, which means my vest stays comfortable and safe.

Here is a quick comparison of comfort features I have noticed:

Feature | 3M Retroreflective Tape | Regular Reflective Tape |

|---|---|---|

Flexibility | High | Medium |

Breathability | Excellent | Fair |

Skin Comfort | Smooth | Sometimes rough |

Durability After Wash | Maintains comfort | May degrade |

I believe comfort is just as important as visibility. If my retroreflective vest feels good, I am more likely to wear it every shift. 3M retroreflective technology gives me peace of mind because I know I am protected and comfortable at the same time. I recommend 3M for anyone who wants workwear that supports safety without sacrificing comfort.

Regular Reflective Material

Regular Reflective Types

When I started working at the gas station, I noticed that not all safety vests use the same reflective materials. Regular reflective tape comes in many forms, and each type has its own strengths. I learned that manufacturers use different compositions to create reflective properties. Some vests use high luster reflective fabric, which is made from polyester or a blend of cotton and polyester. This type shines brightly and has a high reflective coefficient. Other vests feature high reflective fabric with glass bead technology on the front and a polyester backing. The gray front stands out under headlights.

I also see ordinary reflective fabric in some safety vests. This material offers basic reflectance and works well in areas with moderate lighting. Flame retardant reflective fabric protects against fire-related accidents, which is important for workers near flammable materials. Reflective heat transfer vinyl is another option. It uses PES or TPU fabric and gets applied to vests through heat transfer. I often spot elastic reflective fabric in sports and construction vests. This material stretches and comes in different colors. Perforated reflective fabric helps me stay cool during hot shifts because it allows air to flow. Segmented reflective heat transfer vinyl adds flexibility and durability. It can be cut into segments for custom designs.

Reflective Material Type | Composition Description | Reflective Properties |

|---|---|---|

High Luster Reflective Fabric | Polyester or cotton blend | Very bright; high coefficient |

High Reflective Fabric | Glass bead front, polyester backing | Gray front; strong reflectance |

Ordinary Reflective Fabric | Basic reflectance; Oeko-Tex certified | Good for moderate lighting |

Flame Retardant Reflective Fabric | Aramid or cotton backing | Flame-resistant; safety for fire hazards |

Reflective Heat Transfer Vinyl | PES or TPU fabric | Used in construction and sports |

Elastic Reflective Fabric | Spandex backing | Stretchable; colorful |

Perforated Reflective Fabric | Perforated for ventilation | Breathable; ideal for hot conditions |

Segmented Reflective Heat Transfer Vinyl | Cuttable segments; durable | Flexible; washable |

Regular Visibility

Visibility is the main reason I wear safety vests with reflective tape. Regular reflective materials help me stand out, especially when I work near moving vehicles. I notice that high luster and high reflective fabrics shine well under headlights. Ordinary reflective fabric works best in areas with some lighting, but it does not perform as well in total darkness. Flame retardant reflective fabric keeps me safe near fuel pumps, but its reflectance may be lower than other types.

I pay attention to how my vest looks at night. Regular retroreflective tape reflects light back to its source, but the brightness can fade over time. I have seen some vests lose their shine after many washes. Segmented and perforated reflective materials offer good visibility and comfort, but they may not match the performance of premium brands. I always check my vest before each shift to make sure the reflective tape is still effective.

Tip: Stand under a streetlight or shine a flashlight on your vest to test its visibility before starting work.

Regular Durability

Durability matters to me because I wash my safety vests often. Regular reflective materials vary in how well they hold up. High luster and high reflective fabrics usually last longer, but ordinary reflective fabric can wear out quickly. Flame retardant reflective fabric resists fire, but it may lose reflectance after repeated laundering. Reflective heat transfer vinyl and elastic reflective fabric stay flexible, but they can peel or crack if not cared for properly.

I have learned that segmented reflective heat transfer vinyl offers better washability and durability. Perforated reflective fabric keeps me comfortable, but the tiny holes can weaken the material over time. I always follow the care instructions on my vest to extend its life. Regular retroreflective tape may not last as long as 3M products, but proper maintenance helps keep my safety vests in good condition.

Note: Wash your vest in cold water and avoid harsh detergents to protect the reflective tape and retroreflective tape.

Regular Safety Standards

When I started working at the gas station, I wanted to know if my safety vest met the right standards. I learned that regular reflective materials must follow certain rules to keep workers safe. These rules come from organizations like ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration). I always check the label on my vest to see if it meets ANSI/ISEA 107 standards. This standard tells me if my vest has enough reflective material and the right colors for high visibility.

Regular reflective tapes often meet basic safety requirements. Many vests use these tapes in industries like construction, road work, and warehouse jobs. I see them everywhere because they are affordable and easy to find. However, not all regular reflective tapes offer the same level of protection. Some tapes only meet the minimum brightness required by ANSI. Others might lose their reflectivity after a few washes. I always test my vest under different lights to make sure it still works.

Note: I recommend checking for the ANSI/ISEA 107 label before buying any safety vest. This label means the vest passed tests for visibility and durability.

Here is a quick table that helps me compare regular reflective tapes and 3M tapes when it comes to safety standards:

Feature | Regular Reflective Tape | 3M Reflective Tape |

|---|---|---|

Meets ANSI/ISEA 107 | Sometimes | Always |

Retains Reflectivity After Wash | Varies | Consistently High |

Durability | Moderate | Excellent |

Common in Low-Cost Vests | Yes | Less Common |

I noticed that some regular reflective tapes do not last as long as 3M. After several washes, the tape can peel or fade. This makes the vest less visible and less safe. I always follow the care instructions to help my vest last longer. I wash it in cold water and hang it to dry. I avoid ironing the reflective tape because heat can damage it.

Some regular reflective tapes meet only the lowest safety standards. I have seen vests that look bright at first but lose their shine quickly. I learned that 3M tapes usually exceed the minimum requirements. This gives me more confidence when I work at night or in bad weather.

Tip: If you work in a high-risk area, choose a vest that not only meets but exceeds ANSI/ISEA 107 standards. Your safety depends on how visible you are.

I believe that understanding safety standards helps me make better choices. I always look for vests with clear labels and high-quality reflective tape. Regular reflective materials can keep me safe if I choose wisely and take care of my gear. I never take shortcuts with safety because my life and the lives of others depend on it.

Visibility and Safety Comparison

Daytime vs Nighttime Visibility

I always pay close attention to how my safety vests perform in different lighting conditions. During the day, I notice that regular reflective strips provide adequate visibility. They help me stand out, but I do not feel as confident as I do at night. When darkness falls, retroreflective tape becomes essential. I rely on 3M retroreflective technology because it offers improved visibility under headlights and streetlights. Regular reflective tape works, but I see a clear difference in brightness and distance.

Condition | Reflective Strips | Full Reflective Sheeting |

|---|---|---|

Daytime Visibility | Adequate | High |

Nighttime Visibility | Moderate | Excellent |

Adverse Weather | Limited | Superior |

I choose safety vests with 3M retroreflective tape for my night shifts. The technology helps me stay visible in low-light situations, which is critical for my safety. I have seen drivers react faster when my vest shines brightly at night. I believe that retroreflective tape makes a real difference in preventing accidents.

Performance in Weather

Weather can change quickly at the gas station. I have worked through rain, fog, and even snow. I trust 3M’s prismatic retroreflective tape because it maintains visibility when conditions get tough. Water runs off the surface, so the tape keeps reflecting light. Even in heavy rain, I see that 3M retroreflective strips shine under headlights. This gives me peace of mind during stormy shifts.

Other brands like Avery use anti-dew films to keep water from sticking. These films help in fog and after snow, but I notice that 3M signs and safety vests are brighter in rain and snow. This brightness is important for safety in areas with frequent storms. Both brands help reduce accident risks by keeping workers visible, but I prefer 3M for its superior performance.

3M’s prismatic sheeting performs well in wet conditions, allowing water to run off and maintaining visibility.

Even in heavy rain, 3M films effectively reflect headlights, enhancing driver awareness.

Avery’s anti-dew films prevent water from sticking, ensuring clarity in fog and after snow.

Both brands contribute to reducing accident risks by ensuring signs and safety vests remain visible during adverse weather.

Tests indicate that 3M safety vests are brighter than Avery’s in rain and snow, which is crucial for safety in storm-prone areas.

I always check my retroreflective tape before a shift if the weather looks bad. I want to make sure my safety vest will keep me visible no matter what.

Washing and Wear Resistance

I wash my safety vests often, so I need materials that last. I have found that 3M Scotchlite retroreflective tape stands up to repeated washing. It keeps its brightness and flexibility, even after months of use. Studies show that 3M products deliver consistent results with minimal deviation. This means my vest stays reliable over time.

Other reflective strips, like Gear Aid Tenacious Tape, do not last as long. They may peel or lose their shine after a few years. I have seen regular reflective tape wear out faster, especially if I do not follow care instructions. 3M Scotchlite can last up to 10 years, while other brands might only last 5 years.

3M Scotchlite reflective tape is recognized for its durability and high visibility, lasting up to 10 years and enduring repeated washing.

In contrast, other reflective strips like Gear Aid Tenacious Tape have a shorter lifespan of about 5 years and may not adhere as effectively.

3M Scotchlite is designed for durability and repeated washing, making it superior in wash and wear resistance compared to regular reflective strips.

I always follow the care label on my safety vests. I wash them in cold water and hang them to dry. This helps my retroreflective tape stay bright and attached. I recommend choosing safety vests with 3M retroreflective tape for the best wash and wear resistance.

I pay attention to safety vest classes and compliance. Class 3 safety vests offer the highest visibility, with more retroreflective tape and background fabric. I always check that my vest meets the right safety standards for my job. Retroreflective technology and improved visibility help me stay safe every shift.

Safety Standards

When I choose workwear for my job at the gas station, I always check if it meets the right safety standards. These standards help me understand how much protection my vest gives me. I look for labels from organizations like ANSI (American National Standards Institute) and OSHA (Occupational Safety and Health Administration). These groups set rules for high visibility clothing. If my vest meets ANSI/ISEA 107, I know it has enough reflective material and bright colors to keep me safe.

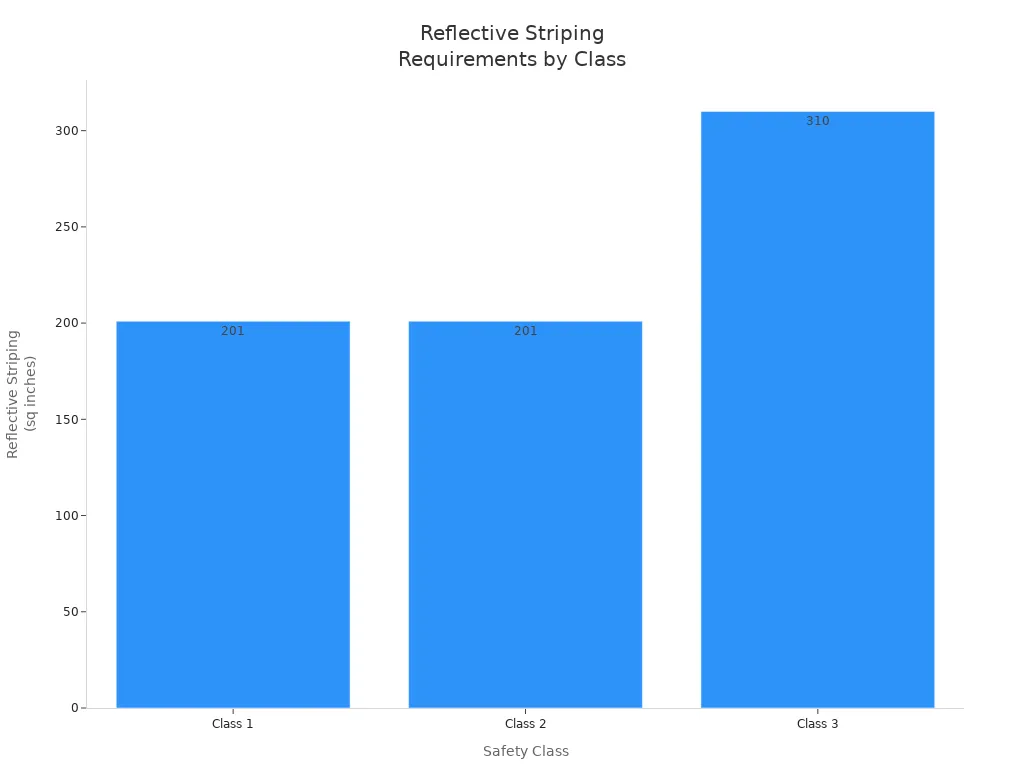

I pay close attention to safety vest classes. Each class offers a different level of visibility. Here is a table that helps me remember the differences:

Safety Vest Class | Description | Typical Use Case |

|---|---|---|

Class 1 | Lowest visibility | Parking attendants |

Class 2 | Medium visibility | Gas station workers, road crews |

Class 3 | Highest visibility | Highway workers, emergency responders |

I always choose Class 2 or Class 3 vests for my shifts. These vests have more reflective tape and brighter background fabric. I feel safer because drivers can see me from farther away. 3M reflective strips usually meet or exceed these standards. Regular reflective tape sometimes meets only the minimum requirements. I test my vest under different lights to make sure it still provides good visibility.

Note: No reflective product can guarantee absolute safety. I stay alert and follow safety rules, even when I wear the best gear.

I learned that safety standards also cover how well the vest holds up after washing. 3M reflective tape keeps its visibility longer than most regular tapes. If my vest loses its shine, I replace it right away. I never take chances with my safety.

I recommend checking for ANSI/ISEA 107 labels before buying any safety vest. This label means the vest passed tests for visibility and durability. I trust 3M because it always meets these standards. Regular reflective tape can work, but I make sure it is certified before I use it.

High Visibility Clothing Standards

ANSI and OSHA

When I started working at the gas station, I realized how important it is to follow ansi and osha standards. These organizations set the rules for high visibility clothing and safety vests. ANSI/ISEA 107 gives clear guidelines for the amount of background and reflective material needed. OSHA makes sure employers keep workers safe by following these rules. I always check if my vest is ansi 107 compliant before I wear it.

I learned that compliance with standards keeps me visible and protected. Gas stations have moving vehicles and low-light conditions, so I need to stand out. Here are some steps I follow to make sure I meet compliance:

I assess my work environment for risks.

I choose garments in bright colors with enough reflective material.

I check for ansi 107 compliant labels on my safety vests.

The table below shows what class 3 safety vests require:

Requirement | Class 3 |

|---|---|

Visibility Distance | At least 1280 feet |

Background Material | At least 1,240 sq in |

Reflective Material | At least 310 sq in |

Additional Features | Sleeves or Class E pants |

These standards help me stay safe during every shift.

Class 1, 2, 3 Vests

I always pay attention to safety vest classes when I pick out my gear. Each class fits a different work environment. I use this table to remember the differences:

Class | Reflective Material (sq in) | Background Material (sq in) | Intended Use Case |

|---|---|---|---|

1 | 155 | 217 | Low-traffic areas |

2 | 201 | 775 | Medium-traffic areas |

3 | 310 | 1,240 | High-intensity traffic areas |

Class 1 vests work for low-traffic spots like parking lots.

Class 2 safety vests fit medium-traffic areas, such as construction zones.

Class 3 safety vests give the most protection. I wear these when I work near busy roads or at night.

I always choose class 3 safety vests for my night shifts. They have more reflective tape and background fabric, which helps drivers see me from far away. I feel safer knowing I meet the highest standards.

Class F vs Class R

I also learned about the difference between Class F and Class R safety vests. This helps me pick the right vest for my shift. Here is a quick comparison:

Class | Visibility Condition | Material Type |

|---|---|---|

F | Daytime | Fluorescent |

R | Night/Dark | Retroreflective |

RF | Both | Combined |

NF | High Daytime | Non-fluorescent |

Class F vests use fluorescent colors, so I wear them during the day. Class R vests use retroreflective tape, which works best at night. Some vests combine both features for all-day protection. I always check the label to make sure my vest matches my work conditions.

Tip: I never skip checking my vest for compliance with standards. My safety depends on it.

Gas Station Workwear Application

Worker Experiences

I have spent years working at gas stations, and I always pay attention to the performance of my gas station workwear. Many coworkers share their stories with me. One friend told me that his vest with 3M reflective strips helped a driver spot him during a late-night shift. He felt safer because the improved visibility gave drivers more time to react. Another coworker tried regular reflective tape but noticed it faded after a few months. She switched to high visibility apparel with premium strips and saw a big difference in how bright her vest looked under headlights.

I often hear that comfort matters just as much as safety. Some vests feel heavy or stiff, especially after several washes. I prefer lightweight designs that let me move easily. When I wear gas station workwear with flexible reflective strips, I stay comfortable during long shifts. I also notice that high-quality tape does not peel or crack, even after repeated use in high-risk environments.

Tip: Ask other workers about their experiences before choosing your next safety vest. Real feedback helps you pick gear that lasts and keeps you safe.

Incident Reports

I have seen a few close calls at my station. One night, a coworker wore a vest with faded reflective tape. A car almost missed him while pulling in. After that, our manager made sure everyone had gas station workwear with bright, reliable strips. I remember another incident where rain made it hard to see. Workers with 3M reflective tape stood out, while others blended into the background. These stories remind me that the right gear can prevent accidents.

Industry reports highlight common challenges with maintaining reflective strip effectiveness. Here is a table that shows what I have learned:

Challenge | Problem Description | Impact |

|---|---|---|

Repeated washing, especially in high-heat conditions, can cause reflective tapes to crack, peel, or lose their reflectivity. | Damaged tape reduces visibility and may lead to safety violations in low-light environments. | |

Color Fading and Loss of Visibility | Frequent washing can cause color fading, reducing visibility and safety compliance. | Fading diminishes the reflective quality and can make the garment non-compliant. |

I always check my vest before each shift. If I see cracks or fading, I replace it right away. Staying visible keeps me and my coworkers safe.

Maintenance Tips

I want my gas station workwear to last as long as possible. I follow these maintenance practices to keep my reflective strips bright and effective:

Avoid bleach and fabric softeners.

Gently clean without scrubbing reflective tape.

Rinse thoroughly and dry in the shade.

For machine washing, wash garments inside-out on a cold, gentle cycle.

Avoid tumble drying to protect reflective tape.

I learned to avoid common mistakes. I never use strong chemical detergents or dry my vest in direct sunlight. I also avoid ironing over the reflective tape. These habits help my high visibility apparel stay bright and compliant.

Note: Regular care extends the life of your vest and keeps you safe in high-risk environments.

I believe that proper maintenance and choosing the right gear make a big difference. My gas station workwear helps me stay visible and protected every shift.

Choosing Reflective Strips

Key Factors

When I select reflective strips for my gas station workwear, I focus on several important factors. I want my vest to keep me safe and comfortable during every shift. I learned that safety experts recommend looking at risk level, material quality, climate adaptability, and strip placement. I use the table below to help me remember what matters most:

Factor | Description |

|---|---|

Risk Level | I assess the visibility class I need for my work area. Class 2 or 3 safety vests work best for busy stations. |

Material Quality | I choose durable fabrics like polyester blends. These materials last longer and feel comfortable. |

Climate Adaptability | I pick short or long sleeves based on the weather. I want my vest to keep me cool in summer and warm in winter. |

Reflective Strip Placement | I make sure strips cover high-visibility areas. Good placement helps drivers see me from every angle. |

I always check these factors before buying a new vest. I want my safety vests to meet the right standards and keep me visible in all conditions.

I see clear differences between 3M and regular reflective strips. 3M strips boost visibility by up to 200% at night, while regular gear often fails in low-light conditions. I trust 3M for lasting durability and compliance with safety standards.

Investing in ANSI-compliant gear saves money over time and keeps me safer at work.

High-visibility clothing improves morale and shows a commitment to safety.

“Being seen clearly is crucial for preventing accidents, especially in high-risk jobs,” says NIOSH. I always choose gear that protects me and lasts.

FAQ

What makes 3M reflective strips safer than regular ones?

I trust 3M strips because they reflect light more effectively. Drivers see me from farther away, especially at night or in bad weather. 3M also meets higher safety standards, which gives me peace of mind during every shift.

How often should I replace my reflective safety vest?

I check my vest before each shift. If I see fading, cracks, or peeling on the reflective strips, I replace it right away. I usually get a new vest every 6 to 12 months, depending on wear.

Can I wash my vest with reflective strips in a washing machine?

Yes, I wash my vest in cold water on a gentle cycle. I always turn it inside out and avoid bleach or fabric softeners. I hang it to dry. This keeps the reflective strips bright and attached.

Do all reflective strips meet ANSI/ISEA 107 standards?

No, not all strips meet these standards. I always look for the ANSI/ISEA 107 label before buying. 3M strips usually meet or exceed these requirements, while some regular strips only meet the minimum.

Are 3M reflective strips comfortable to wear?

I find 3M strips flexible and smooth. They do not scratch or irritate my skin. My vest stays comfortable, even after many washes. I can move freely during long shifts.

What is the difference between fluorescent and reflective materials?

Fluorescent materials help me stand out during the day. Reflective materials shine under headlights at night. I choose vests with both for all-day visibility.

Where can I buy high-quality reflective safety vests?

I buy my vests from safety supply stores or trusted online retailers. I always check for ANSI/ISEA 107 compliance and look for 3M branding for the best quality.

Tip: Always inspect your vest before each shift. Staying visible keeps you safe.