Bulk Workwear Pricing and Competitive Quotes from Chinese Exporters

You often see bulk workwear pricing from Chinese exporters range between $1.80 and $5.00 per piece. Your final cost depends on fabric type, order quantity, and customization features like logo embroidery or HD printing. Many suppliers offer OEM services, which let you add your own branding. Comparing different suppliers helps you secure both quality and value.

Typical Discount | Notes | |

|---|---|---|

100–299 pcs | 30%–40% | Basic wholesale entry |

300–499 pcs | 40%–50% | Better fabric cost sharing |

500–999 pcs | 50%–55% | Production-line optimization |

1000+ pcs | 55%–65% | Highest margin, best price |

Bulk material sourcing lowers unit cost.

Production efficiency boosts output.

Higher quantities attract better pricing tiers.

Key Takeaways

Bulk workwear pricing from Chinese exporters typically ranges from $1.80 to $5.00 per piece, influenced by fabric type and order quantity.

Higher order quantities lead to better pricing tiers, with discounts increasing as you order more pieces.

Choosing quality fabrics like cotton twill ensures durability and comfort, impacting the overall cost and performance of workwear.

Always verify that workwear meets recognized durability and safety standards to ensure reliability in demanding environments.

Customization options, such as logo embroidery, can enhance your brand but may increase overall costs; budget accordingly.

Understand shipping terms like FOB and CIF to manage your total landed cost effectively and avoid unexpected fees.

Request samples before placing large orders to assess quality and ensure the product meets your specifications.

Build strong relationships with suppliers to improve pricing and service, while remaining aware of potential risks like quality control.

Bulk Workwear Pricing Factors

Material Quality

Fabric Types and Cost Impact

You need to pay close attention to fabric selection when evaluating bulk workwear pricing. Chinese exporters often use cotton twill fabric for its durability and comfort. The quality of cotton, including its origin and processing method, directly affects the final price. Reliable suppliers source high-quality cotton, which increases the price per meter but ensures better performance and longevity. Meticulous craftsmanship also adds value by enhancing the garment’s texture and durability. Many global brands, such as H&M and Nike, trust these materials, which justifies higher costs and builds market trust.

Aspect | Description |

|---|---|

Common Material | Cotton twill fabric is frequently used in Chinese-manufactured workwear. |

Quality Impact on Pricing | The quality of cotton, including its origin and processing, significantly influences pricing. |

Craftsmanship | Meticulous craftsmanship enhances durability and texture, affecting the overall cost. |

Supplier Standards | Sourcing from reliable suppliers ensures high-quality cotton, impacting the price per meter. |

Certification | Collaborations with certified partners ensure quality and environmental safety, influencing cost. |

Market Trust | Global brands like H&M and Nike trust this fabric, indicating its quality and justifying higher prices. |

Durability Standards

You should always check if the workwear meets recognized durability standards. Chinese exporters follow several industry codes to guarantee product reliability. These standards cover everything from medical protective clothing to garments designed for chemical or electrostatic protection. Compliance with these codes ensures that your workwear will withstand demanding environments and frequent washing.

Standard Code | Description |

|---|---|

GB 19082-2009 | Technical requirements for disposable medical protective clothing. |

GB/T 24539-2009 | General technical specifications for chemical protective clothing. |

GB/T 23462-2009 | Standards for particulate protective garments. |

GB 12014-2019 | General specifications for electrostatic protective clothing. |

GB 19082-2023 | Major updates include new indicators like biocompatibility and seam strength. |

Order Quantity

Price Breaks by Volume

Order quantity plays a major role in bulk workwear pricing. Suppliers set minimum order quantity (MOQ) requirements to cover production and shipping costs. When you place larger orders, you benefit from economies of scale. Factories can optimize production lines, which reduces the cost per unit. High-volume orders are more profitable for suppliers, so they offer better discounts. Smaller orders, on the other hand, usually come with higher per-piece costs.

Suppliers have MOQ requirements to ensure production and shipping costs are covered.

Larger orders allow suppliers to reduce the cost per unit, leading to economies of scale.

High volume orders are more profitable for factories, resulting in higher profit margins at lower rates per unit.

Smaller orders may incur higher costs due to lower economies of scale.

There is a direct relationship between price and order quantity: larger volumes yield greater discounts, while smaller volumes result in higher per-piece costs.

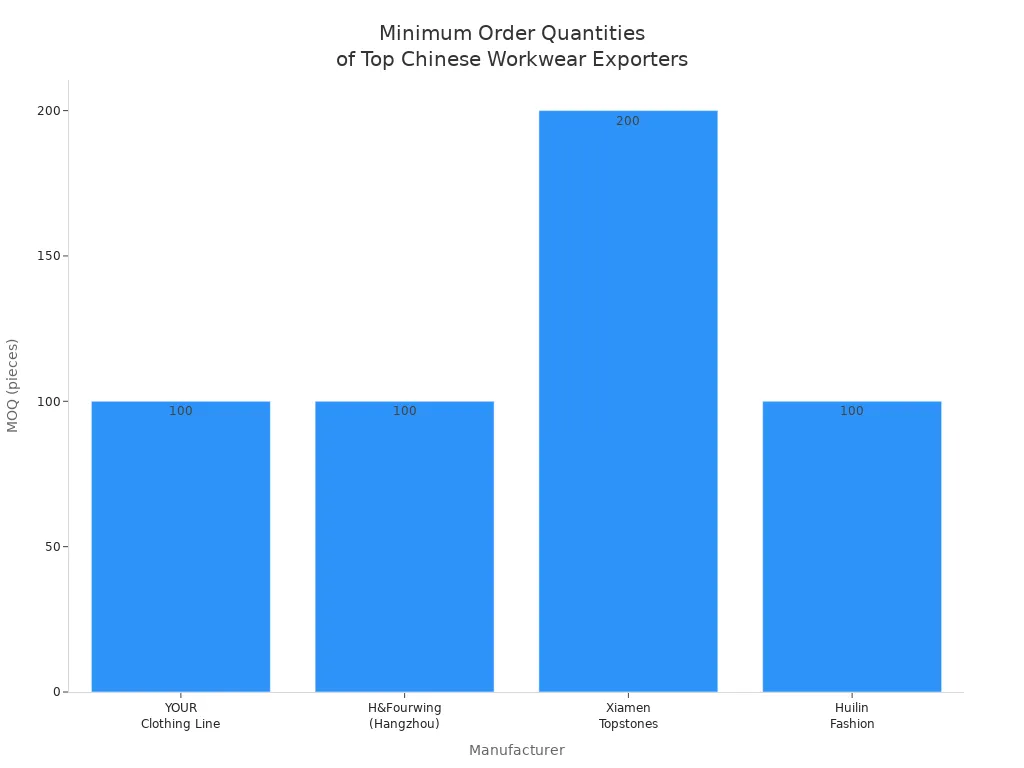

Minimum Order Size

You need to know the standard MOQs before negotiating with Chinese exporters. Most leading manufacturers require a minimum of 100 to 200 pieces per style or design. Some suppliers may offer negotiable terms, but you should always confirm this before finalizing your order.

Manufacturer | MOQ |

|---|---|

YOUR Clothing Line | 100 units per style per color |

H&Fourwing (Hangzhou) | 100 pieces/style |

Xiamen Topstones Import & Export Co., Ltd. | 200 pieces/design |

Shandong Jining Ruyi Woolen Textile Co., Ltd. | Negotiable |

Huilin Fashion | 100 pieces per style |

Customization Options

OEM Services Overview

Most Chinese exporters offer OEM services, which allow you to add your own branding and design elements. You can request logo embroidery, HD printing, or even custom packaging. These services help you create a unique product that stands out in your market. Design assistance is often available to help you refine logos and select colors. Private labeling and unique packaging options further enhance your brand’s presentation.

Tip: Always ask your supplier for a sample of their customization work to assess quality before placing a large order.

Branding and Design Costs

Customization adds value but also increases the overall cost. You should budget for these expenses when calculating bulk workwear pricing. For example, adding a customized logo or graphic typically costs around $0.70 per set, with a minimum order of 100 sets. Custom packaging starts at $0.20 per set for orders of 1,000 or more. These costs can vary depending on the complexity of your design and the materials used.

Customization Type | Cost per Set | Minimum Order |

|---|---|---|

Customized logo | $0.70 | 100 sets |

Customized packaging | $0.20 | 1,000 sets |

Graphic customization | $0.70 | 100 sets |

You can also request design assistance, private labeling, and unique packaging to further differentiate your products.

Compliance & Certifications

Safety Standards

You must ensure that your supplier meets international safety standards when sourcing workwear from China. These standards guarantee that garments protect workers in hazardous environments and comply with regulations in your target market. Suppliers who follow recognized safety codes demonstrate their commitment to quality and reliability.

Standard | Region | Key Requirements |

|---|---|---|

ANSI/ISEA 107 | USA | Minimum reflectance of 330 cd/lux/m² and Yellowness Index ≥ 0.70 |

EN ISO 20471 | Europe | Three performance classes based on visibility levels and garment design |

AS/NZS 4602.1 | Australia/New Zealand | Rigorous wash durability requirements after 25+ cycles |

You should expect pricing for safety vests to range from $2.50 to $5.50, depending on features and order quantities. Suppliers often offer volume discounts, which help you manage your budget more effectively.

Required Documentation

You need to request proper documentation from your supplier to verify compliance and certifications. This paperwork protects your business and ensures smooth customs clearance. Common certifications include CE Marking, RoHS, ISO 9001, and BSCI. Each certification addresses different aspects of product safety, quality, and ethical sourcing.

Certification | Description | Impact on Supplier Selection |

|---|---|---|

CE Marking | Ensures compliance with EU safety, health, and environmental standards. | Indicates commitment to quality and safety for European markets. |

RoHS Compliance | Restricts hazardous materials in products. | Essential for suppliers of electronic components, ensuring environmental safety. |

ISO 9001 | Focuses on quality management and customer satisfaction. | Demonstrates ability to meet regulatory and customer requirements. |

BSCI Certification | Addresses social compliance and labor standards. | Key indicator of ethical sourcing and social responsibility commitment. |

Tip: Always ask for copies of certifications before finalizing your order. This step helps you avoid delays and unexpected costs during importation.

Shipping Terms

FOB vs. CIF

You must understand shipping terms to accurately calculate your total landed cost. Chinese exporters typically offer two main options: FOB (Free On Board) and CIF (Cost, Insurance, and Freight).

CIF may seem convenient for new importers as it relieves them from dealing with freight details, but it often results in higher costs due to additional fees charged by suppliers for handling freight forwarding.

FOB provides better control over freight and costs, allowing you to work with your own freight forwarders. This approach leads to more accurate information and better handling of issues that arise.

Choosing FOB allows for separate invoicing for transportation, which can help you avoid unexpected tariff charges. Under CIF, the seller chooses the carrier, which may lead to higher costs and less control over the shipment, potentially impacting cash flow due to unpredictable transit times.

CIF terms include ocean transportation and insurance costs in the commercial invoice, leading to higher tariff charges. For example, if ocean freight is $4000 and the tariff is 3%, the total tariff expense would be $120, increasing the overall landed cost.

You should compare both options and choose the one that best fits your logistics strategy and budget. Understanding these terms helps you make informed decisions and optimize Bulk Workwear Pricing.

Lead Times and Logistics

You need to plan for lead times when ordering bulk workwear from China. Average production and shipping times range from 30 to 90 days. Several factors can affect delivery schedules:

Seasonal factors, such as Chinese New Year and Golden Week, often cause significant delays.

Supply chain issues, including shortages of raw materials and reliance on secondary suppliers, may disrupt timelines.

Operational delays, such as changes in product specifications or failed quality inspections, can push back delivery dates.

Logistics bottlenecks, like port crowding and sea freight delays, also impact arrival times.

You should communicate regularly with your supplier and monitor these factors to ensure timely delivery. Advance planning and clear agreements help you avoid costly disruptions and keep your project on track.

Requesting and Comparing Quotes

You need to compare prices, fabrics, and shipping options to secure the best value when sourcing workwear from China. A systematic approach helps you avoid costly mistakes and ensures you receive accurate, competitive offers.

Information to Provide

Supplying clear and complete information to your suppliers sets the foundation for accurate quotes. You should focus on three main areas:

Product Specs

You must specify every detail about your workwear order. List the materials, colors, sizes, and packaging requirements. Clear specifications minimize miscommunication. This clarity prevents production errors and unexpected costs. When you provide detailed specs, suppliers can calculate true costs and deliver precise quotes.

Quantity and Delivery

State your required order quantity and preferred delivery timeline. Suppliers need this information to assess production capacity and logistics. If you have flexibility in delivery dates, mention it. This flexibility can sometimes lead to better pricing or faster turnaround.

Customization Needs

Describe any customization you require, such as logo embroidery, HD printing, or special packaging. Attach artwork files or design references if available. The more detail you provide, the more accurate your quote will be. Customization often affects both price and lead time.

Tip: Always request a sample before confirming a large order. This step helps you verify quality and avoid surprises.

Evaluating Quotes

Once you receive quotes, you need to analyze them carefully. Do not focus only on the lowest price. Review the breakdown, check for hidden costs, and confirm quality terms.

Price Breakdown

A comprehensive price breakdown reveals the true cost of your order. You should look for these key components:

Product details: Confirm the product name, drawing number, and quantity match your request.

Shipping method: Check the incoterms (such as EXW, FOB, DDP) to understand your responsibilities and costs.

Terms of payment: Make sure payment terms are clear for both samples and mass production.

Currency exchange: See if the quote mentions the exchange rate to protect against fluctuations.

This level of detail helps you compare offers on an equal basis and avoid misunderstandings.

Hidden Costs

You must identify any hidden costs that could impact your landed cost. These often appear after you place your order. Common hidden fees include customs duties, last-mile delivery charges, and return handling. Review the table below to understand their impact:

Hidden Cost | Impact on Landed Cost |

|---|---|

Customs Duties | Adds 5–10% |

Last-Mile Fees | Adds 5–10% |

Returns | Adds 5–10% |

Ask your supplier to clarify which costs are included and which are not. This step protects your budget and prevents unpleasant surprises.

Quality Clauses

You should check for quality clauses in every quote. These clauses outline standards for materials, workmanship, and inspection. They also specify what happens if products fail to meet requirements. Clear quality terms protect your interests and set expectations for both parties.

Note: Always request written confirmation of quality standards and inspection procedures.

Negotiation Tips

Negotiation is a key part of securing the best deal. You can often improve pricing or terms by following proven strategies.

Pricing Strategies

Building a personal relationship with your supplier can lead to better prices. Face-to-face meetings help establish trust. Regular visits show your commitment and may result in preferential treatment. Suppliers often reserve their best rates for buyers they know and trust.

Using Multiple Offers

You should request quotes from several suppliers. Use these offers to negotiate better terms. Let suppliers know you are comparing options. This approach encourages them to offer their most competitive pricing and service.

Pro Tip: Presenting multiple quotes during negotiation signals that you are an informed buyer. Suppliers are more likely to match or beat competitor offers.

When you follow these steps, you gain control over Bulk Workwear Pricing and ensure you receive the best value for your investment.

Reliable Chinese Exporters

Verification Steps

Business License Check

You should always verify a supplier’s business license before placing a bulk order. Request essential documents such as the business license, ISO certifications, and factory certifications. These documents confirm the manufacturer’s legitimacy and compliance with industry regulations. You can also check the supplier’s background by reviewing their experience and past partnerships. Reliable exporters will provide these documents promptly and answer your questions about their credentials.

Factory Audit

A factory audit gives you deeper insight into the supplier’s operations. If possible, visit the factory to observe production processes and assess working conditions. You should inquire about quality control measures, including inspection points and certifications like ISO 9001. Request product samples to evaluate quality firsthand. Scrutinize quotations to ensure transparency and avoid hidden costs. Assess transportation options and costs to determine overall profitability. Discuss minimum order quantities and clarify production lead times to align with your inventory needs. Reliable suppliers will welcome audits and provide clear information about their customization capabilities.

Tip: Requesting samples and conducting audits help you avoid costly mistakes and ensure the supplier meets your standards.

Red Flags

Unrealistic Prices

You may encounter suppliers offering prices that seem too good to be true. Unrealistic pricing often signals unreliable or fraudulent exporters. Some suppliers disappear after receiving payments, while others deliver defective or incorrect products. Misrepresentation is common, with middlemen posing as manufacturers or using misleading factory images. Fake certifications and supplier badges also raise concerns.

Poor Communication

Poor communication is another warning sign. Suppliers who avoid answering questions or provide vague responses may not be trustworthy. Edited photos and exaggerated product descriptions can mislead you. Products may not meet advertised specifications, and lack of quality checks can result in poorly manufactured goods. Non-compliance with regulations can lead to legal issues and import delays.

Common Red Flags Table:

Red Flag | What It Means |

|---|---|

Unrealistic low prices | Possible fraud or poor quality |

Scam risk | |

Fake certifications | Lack of compliance |

Poor communication | Unreliable service |

Misleading images/descriptions | Misrepresentation |

Note: Always verify supplier credentials and maintain clear communication to protect your investment.

Sourcing Platforms

Alibaba, Global Sources

You can find reliable Chinese workwear exporters on major sourcing platforms such as Alibaba and Global Sources. These platforms allow you to review supplier profiles, check certifications, and compare product offerings. You should use platform filters to identify verified manufacturers and read buyer reviews for additional assurance. Scrutinize quotations and request samples to confirm product quality.

Trade Shows

Attending trade shows in China offers valuable opportunities to connect with reputable exporters. The China International Clothing & Accessories Fair (CHIC), held in Shanghai and Shenzhen, is the largest professional apparel exhibition in the country. CHIC covers a wide range of categories, including workwear, and attracts established manufacturers. The Canton Fair in Guangzhou, held twice a year, features a dedicated phase for textiles and garments. This event is especially beneficial for high-volume buyers seeking direct relationships with reliable suppliers.

Visiting trade shows lets you meet suppliers face-to-face, inspect product samples, and negotiate terms directly. You gain firsthand knowledge of the exporter’s capabilities and build trust for future orders.

Maximizing Value & Avoiding Pitfalls

Cost vs. Quality

Balancing Budget and Durability

You face a constant challenge when sourcing bulk workwear: balancing cost and quality. Many buyers blend materials like cotton and rayon to achieve a good mix of affordability and durability. If you focus only on cost, you risk receiving lower-quality products that can damage your brand reputation. On the other hand, prioritizing quality alone may drive up expenses and reduce your competitiveness. A balanced approach helps you maintain sustainable profitability and ensures your workwear meets both budget and performance needs.

Key considerations for balancing cost and quality:

Use blended fabrics to optimize price and durability.

Avoid sacrificing quality for short-term savings.

Consider long-term brand impact when making purchasing decisions.

Strive for a middle ground that supports both cost control and product reliability.

Supplier Relationships

Building strong relationships with Chinese suppliers offers several advantages. You can enter the market quickly and launch new products faster. Outsourcing production reduces your need to invest in factories or hire staff, which saves money. Chinese manufacturers provide flexibility, allowing you to adjust order sizes based on demand. They also support scalability, handling large orders as your business grows. You can focus on marketing and expansion while your supplier manages production.

However, you must remain aware of potential risks. Quality control can become an issue if you lack direct oversight. Production timelines may slip if your orders are not prioritized. Intellectual property risks exist, so secure your IP rights before starting production.

Benefits:

Cost-effectiveness

Flexibility and scalability

Focus on growth

Risks:

Quality control issues

Timeline delays

Intellectual property concerns

Sample Orders

Pre-Production Samples

Ordering pre-production samples is a critical step in the sourcing process. You should start by defining exactly what you want, including materials, sizes, and features. Research and vet suppliers to ensure they have a solid track record. Once you select a supplier, request a sample and discuss any fees or shipping options. Providing clear product specifications, such as CAD files, design drawings, bill of materials, size tables, color codes, and reference samples, helps avoid delays and miscommunication.

Sample order process:

Define product specifications.

Find and vet suppliers.

Request samples and clarify fees.

Evaluation Criteria

When you receive samples, assess them using clear criteria. Check the physical appearance for flaws and color accuracy. Test functionality, especially for garments with specific durability requirements. Evaluate packaging to ensure it protects the product during transit. Reliable suppliers deliver on schedule, follow your requirements, and show resourcefulness in meeting your needs. Look for vendors with experience serving brands similar to yours.

Evaluation checklist:

Physical appearance

Functionality testing

Packaging quality

Delivery reliability

Supplier expertise

Payment Terms

Secure Methods

Selecting secure payment methods protects your investment. Telegraphic Transfer (T/T) works well for trusted suppliers and small to medium orders, offering speed but limited buyer protection. Letters of Credit (L/C) suit large orders, providing bank-guaranteed security but requiring complex paperwork. Alibaba Trade Assurance offers escrow protection and dispute support for first-time transactions on the platform.

Payment Method | Best For | Advantages | Disadvantages | Risk Level |

|---|---|---|---|---|

T/T (Telegraphic Transfer) | Trusted suppliers, small/medium orders | Quick, globally accepted | No buyer protection before shipment | Medium |

L/C (Letter of Credit) | Large government/corporate orders | Secure, bank-guaranteed payment | Complex paperwork, higher fees | Low |

Alibaba Trade Assurance | First-time suppliers | Escrow protection, dispute support | Limited to Alibaba platform | Low |

Deposit Arrangements

Chinese exporters typically require a 30% deposit upfront, with the balance due after shipment and presentation of the bill of lading. Trusted clients may access open account terms, allowing payment 30–60 days after shipment.

Payment Term | Description |

|---|---|

30% Deposit, Balance Due After B/L | Pay 30% upfront, settle the rest after shipping with bill of lading. |

Open Account (O/A) Terms | For trusted clients, pay balance 30-60 days after shipment. |

Tip: Always confirm payment terms before placing your order to avoid misunderstandings and protect your cash flow.

After-Sales Support

Warranty Policies

You need to pay close attention to warranty policies when sourcing bulk workwear from Chinese exporters. Reliable suppliers always include clear quality clauses in their contracts. These clauses protect you if you receive defective products. You can expect options such as returns, replacements, or credits for items that fail inspection. Suppliers who value long-term partnerships will outline these terms before you place your order.

Most reputable exporters establish inspection protocols. You should review these protocols with your supplier. Inspection procedures often cover material quality, stitching, and finishing. If you discover defects during inspection, you can request compensation based on the contract terms. Some suppliers offer warranties that last from three months up to one year, depending on the product type and usage environment.

A well-defined warranty policy reduces your risk. You avoid unexpected costs and maintain your brand reputation. Always ask for written documentation of warranty coverage. This step ensures you understand your rights and responsibilities.

Tip: Request sample warranty documents before finalizing your order. This practice helps you compare suppliers and choose the most reliable partner.

Communication Channels

Efficient communication channels play a vital role in after-sales support. You should expect fast response times from reputable Chinese exporters. Many suppliers respond to inquiries within five hours. Quick replies show a supplier’s commitment to customer service and problem resolution.

You can reach most exporters through multiple channels. Common options include email, instant messaging apps like WeChat or WhatsApp, and dedicated customer service portals. Some suppliers assign account managers to handle your orders and after-sales issues. This direct contact streamlines communication and speeds up solutions.

Consider the following table to compare common communication channels:

Channel | Typical Response Time | Best Use Case |

|---|---|---|

≤5 hours | Formal documentation | |

WeChat/WhatsApp | ≤2 hours | Urgent queries, quick updates |

Customer Portal | ≤24 hours | Order tracking, support tickets |

You should test each channel before placing a large order. Send a simple inquiry and measure the response time. Reliable suppliers will reply promptly and provide clear answers.

Note: Consistent and transparent communication builds trust. You resolve issues faster and strengthen your business relationship.

You gain peace of mind when your supplier offers robust after-sales support. Warranty policies and responsive communication channels ensure you receive quality products and timely assistance. These factors help you avoid costly mistakes and maintain smooth operations.

You secure the best bulk workwear pricing by following a proven process.

Investigate supplier reputation and review client feedback.

Request samples to assess product standards.

Understand and negotiate minimum order quantities.

Compare pricing across vendors.

Evaluate communication quality.

Verify compliance with safety standards.

Assess shipping options and delivery timelines.

Strong supplier relationships and product testing improve outcomes. Prioritize value, quality, and reliability. Next, reach out to verified exporters and request comprehensive quotes to start your sourcing journey.

FAQ

What is the typical lead time for bulk workwear orders?

You can expect lead times of 30 to 90 days. Production schedules depend on order size, customization, and seasonal demand. Always confirm timelines with your supplier before placing an order.

How do you verify a Chinese exporter’s reliability?

You should request business licenses, certifications, and references. Use sourcing platforms with verified badges. Consider a factory audit or request samples to check quality firsthand.

Can you request samples before placing a large order?

Yes, you can. Most suppliers offer pre-production samples for a fee. This step helps you evaluate material quality, workmanship, and customization accuracy before committing to bulk production.

What payment methods are safest for international orders?

You should use secure methods like Letters of Credit, Alibaba Trade Assurance, or Telegraphic Transfer (T/T) with trusted suppliers. These options protect your funds and reduce transaction risks.

How do you handle defective or non-compliant products?

You need to review the supplier’s warranty and return policy. Reliable exporters offer replacements, credits, or refunds for defective items. Always include quality clauses in your contract.

What certifications should you check for workwear imports?

You should look for CE Marking, ISO 9001, and BSCI for quality and social compliance. For safety garments, check ANSI/ISEA 107 or EN ISO 20471, depending on your market.

Are there hidden costs when importing from China?

Yes, you may face customs duties, last-mile delivery fees, and return charges. Request a full cost breakdown from your supplier to avoid surprises.