Key Metrics for Bulk Convenience Store Uniform Production

When I manage bulk orders for convenience store uniforms, I always track key metrics to ensure the best results. I focus on uniform quality, production speed, cost, order accuracy, and supplier reliability. Each metric shapes the group uniform program and helps me deliver uniforms that meet every need. By monitoring these key metrics, I improve uniform programs and raise efficiency. For example, high uniform quality boosts satisfaction, while accurate orders build trust. The table below shows how each key metric impacts operational efficiency in uniform management:

Metric | Impact on Operational Efficiency |

|---|---|

Minőség | Enhances customer satisfaction and reduces rework costs. |

Production Speed | Ensures timely delivery and meets customer commitments, improving overall performance. |

Cost | Lower procurement costs through better supplier selection and planning. |

Order Accuracy | Reduces errors and enhances customer trust, leading to repeat business. |

Supplier Reliability | Strong relationships lead to consistent performance and fewer disruptions in operations. |

I use real-time inventory tracking and data-driven administrative efficiency techniques to optimize every group uniform program. These practices help me streamline the process and highlight bulk order advantages for every group store for uniforms.

A legfontosabb tudnivalók

Prioritize uniform quality to enhance customer satisfaction and reduce rework costs.

Monitor production speed to ensure timely delivery and meet customer commitments.

Manage costs effectively by comparing suppliers and optimizing material and labor expenses.

Ensure order accuracy to build trust and encourage repeat business through careful verification.

Utilize real-time inventory tracking to streamline operations and prevent stock issues.

Build strong relationships with reliable suppliers to maintain consistent quality and timely deliveries.

Focus on customer metrics like acquisition cost and lifetime value to improve long-term success.

Regularly review and adjust your uniform program based on feedback and performance metrics.

Key Metrics Overview

Uniform Quality

Uniform quality stands at the core of every group uniform program I manage. High-quality uniforms create a strong first impression and support operational efficiency. When I select uniforms for a group, I always focus on two main aspects: fabric durability and stitching.

Fabric Durability

Fabric durability determines how long uniforms last under daily wear and tear. I always choose materials that can withstand frequent washing and rough handling. I rely on rigorous material testing and durability assessments to ensure every uniform meets industry standards. My process includes:

Initial fabric selection based on strength and comfort

Detailed quality assurance process with material inspections

Final product evaluation for wear resistance

Effective quality assurance in bulk uniform production relies on clear standards and continuous improvement. I use precise fit testing and durability assessments to guarantee uniforms perform reliably. The table below shows how measurement specifications and tolerances play a role in uniform management:

Aspect | Leírás |

|---|---|

Measurement Specifications | Critical for quality control; involves setting tolerances for each measurement point. |

Tolerance | Acceptable margin for error during bulk production, expressed as (+ / -) in the spec sheet. |

Role of Technical Designer | Must consider necessary tolerances when creating the spec sheet. |

Stitching

Stitching quality impacts both the appearance and longevity of uniforms. I inspect every uniform for strong seams and consistent stitching. Systematic inspections help me catch defects early in the process. Uniform programs that prioritize stitching quality reduce rework and improve efficiency. My approach includes:

Design verification for seam placement

Systematic inspections during production

Performance testing for seam strength

When employees wear high-quality, thoughtfully designed uniforms, morale and engagement rise. Uniform programs not only boost employee morale but also enhance operational efficiency.

Production Speed

Production speed is essential for meeting deadlines and keeping group uniform programs on track. I measure speed using two key metrics: lead time and throughput.

Lead Time

Lead time measures how quickly I can deliver uniforms after receiving an order. Short lead times help me respond to urgent requests and maintain customer satisfaction. I monitor every step in the process to identify delays and improve efficiency.

Throughput

Throughput tracks the number of uniforms produced within a specific period. High throughput means I can fulfill large orders for group uniform programs without sacrificing quality. I optimize the process by balancing labor and equipment to maximize output.

Uniform programs that focus on production speed unlock new revenue streams through strategic upselling and personalization. Fast delivery encourages repeat business and strengthens customer loyalty.

Cost per Uniform

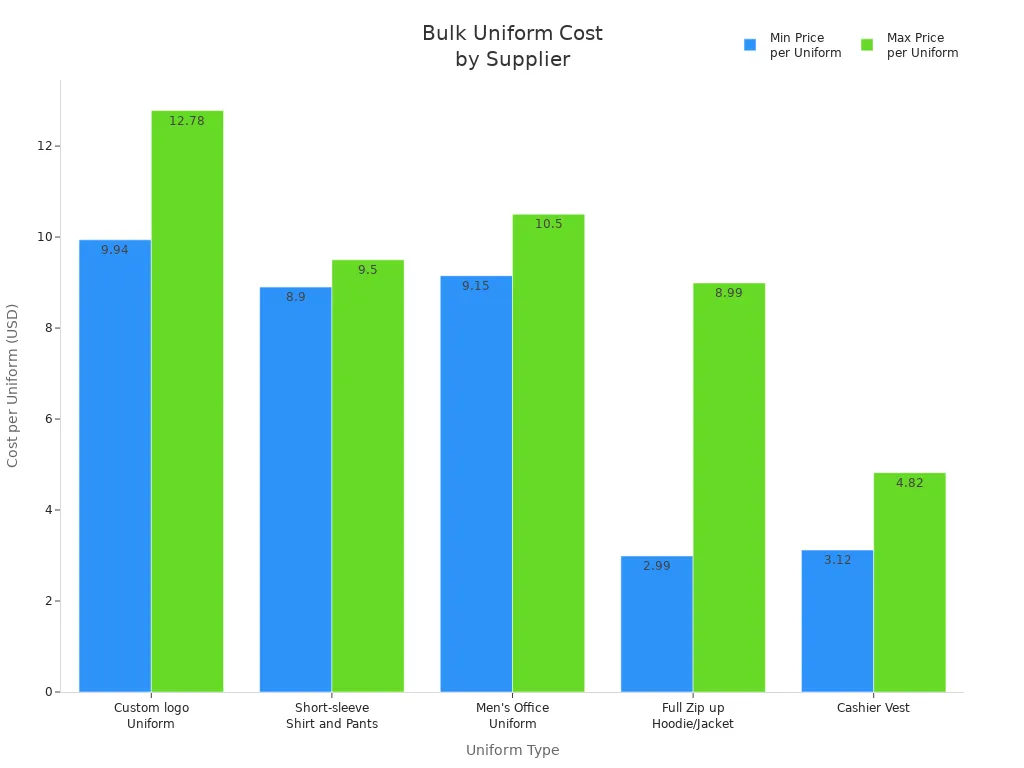

Cost per uniform affects pricing and profitability for every group uniform program. I break down costs into material and labor components to manage expenses and improve efficiency.

Material Cost

Material cost covers the price of raw materials used in manufacturing uniforms. I compare suppliers to find the best balance between quality and price. The table below shows typical costs for bulk uniform orders in the convenience store sector:

Beszállító | Uniform Type | Ártartomány | Minimum Order |

|---|---|---|---|

Henan Chiwai International Trade Co., Ltd. | Custom logo Convenience Store Uniform | 100 pieces | |

Shenzhen Definite Industrial Co., Ltd. | Short-sleeve Shirt and Pants | $8.90 – $9.50 | 500 sets |

Nanchang Triple Crown Imp & Exp Co., Ltd. | Men’s Office Business Uniform | $9.15 – $10.50 | 20 pieces |

Shenzhen Feiny Clothing Co., Ltd. | Full Zip up Hoodie and Jacket | $2.99 – $8.99 | 100 pieces |

N/A | Cashier Vest | $3.12 – $4.82 | 1000 pieces |

Raw materials can cost between $1.50 and $3.59 per shirt, depending on quality. I always choose materials that meet both durability and budget requirements for group uniform programs.

Labor Cost

Labor cost includes wages and benefits for workers involved in the production process. Skilled labor can significantly improve the quality of uniforms. The process of making shirts involves several labor-intensive phases. Direct labor costs range from $0.19 to $2.10 per shirt, influenced by the skill level of the workers. Both direct labor and material costs are essential for determining the total manufacturing cost, which impacts pricing and profitability.

Uniform programs that manage costs effectively can scale across multiple locations and maintain consistency. Compliance with industry and safety standards remains crucial for every group uniform program.

Tip: Uniform programs that focus on quality, speed, and cost management drive efficiency and support long-term success for group stores.

Implementing a group uniform program can enhance customer loyalty and encourage repeat business.

Expanding customer loyalty through group uniform programs leads to scaling across multiple locations.

Unlocking new revenue streams is possible through strategic upselling and personalization.

High-quality uniforms boost employee morale and engagement.

Uniform programs improve operational efficiency.

Compliance with industry and safety standards is essential.

Order Accuracy

Order accuracy plays a critical role in every uniform program I manage. When I process bulk orders for uniforms, I pay close attention to the details. Accurate orders ensure that every group receives the correct uniforms, which builds trust and keeps customers coming back. I have learned that even small mistakes can disrupt operations and damage relationships.

Correct Items

I always verify each order before production begins. My process starts with a detailed review of the uniform specifications for every group. I check sizes, colors, and styles to match the requirements of the uniform program. I use order management software to track every item and prevent errors. When I confirm the correct uniforms for each group, I reduce the risk of costly returns and delays.

I rely on a checklist to ensure accuracy:

Review uniform specifications for each group

Confirm quantities and sizes for every uniform program

Match colors and styles to the order details

Double-check the order before production starts

When I deliver the correct uniforms, customers feel confident in my service. This attention to detail strengthens relationships and encourages repeat business.

Packing

Packing is another key part of order accuracy. I organize uniforms by group and label each package clearly. I use quality packing materials to protect uniforms during shipping. My team follows a strict packing protocol to avoid mix-ups and damage.

I have found that effective packing improves customer satisfaction. When uniforms arrive in perfect condition, customers appreciate the care I put into every order. Accurate packaging also supports the success of uniform programs by making distribution easier for each group.

Megjegyzés: Effective management of shipping logistics, including accurate packaging and timely delivery, significantly enhances customer satisfaction, which is crucial for repeat purchases.

I focus on building strong relationships with customers. I listen to their needs and provide excellent service throughout the uniform program. This approach fosters loyalty and encourages customers to choose my uniforms again.

Here is how order accuracy impacts customer retention and repeat business in uniform programs:

Accurate uniforms and packing build trust with customers

Timely delivery of uniforms increases satisfaction

Strong relationships encourage repeat purchases

Excellent service supports long-term success for every uniform program

I believe that order accuracy is the foundation of a successful uniform program. When I deliver the right uniforms, packed with care, I help every group achieve their goals.

Real-Time Inventory Tracking

When I manage uniform programs for group stores, I rely on real-time inventory tracking to keep everything running smoothly. This approach gives me instant access to stock levels, order status, and uniform availability. I use inventory management software and other tools to automate these tasks, which saves time and reduces mistakes. Real-time inventory tracking helps me avoid stockouts, overstocking, and costly errors in every uniform program.

Itt van néhány key benefits I have seen from using real-time inventory tracking in my uniform programs:

Előny | Leírás |

|---|---|

Javított hatékonyság | I can view the exact status of each uniform at any time, which streamlines operations. |

Reduced Errors | Real-time data minimizes mistakes in uniform tracking and distribution. |

Enhanced Employee Experience | Employees always have the correct uniforms when needed, improving satisfaction and professionalism. |

Better Resource Allocation | I can reorder uniforms on time and manage stock levels, preventing shortages or overstocking. |

I also notice that automation eliminates manual processes, which reduces errors and saves time for my team. Real-time updates prevent stock shortages and overstocking, making uniform management much easier.

Inventory Days on Hand

Inventory Days on Hand (DOH) tells me how long my current uniforms will last before I need to reorder. I use this metric to measure how efficiently I manage inventory in my uniform programs. A lower DOH means I move uniforms quickly, which keeps cash free for other needs. If my DOH is high, I know I might have too many uniforms sitting in storage, which ties up money and space.

When I track DOH, I can spot trends and make better decisions about ordering. If I see that uniforms are moving slowly, I adjust my orders or run promotions to clear out extra stock. This keeps my uniform programs lean and efficient.

Shrinkage

Shrinkage happens when uniforms go missing due to theft or errors. This problem can hurt profitability in any group store for uniforms. I have seen how shrinkage leads to lost revenue and makes inventory management harder. For multi-site uniform programs, shrinkage can be even more challenging because it is tough to keep track of uniforms across many locations.

To fight shrinkage, I use regular audits and train my staff to follow best practices. I also invest in software and AI systems for loss prevention. These steps help me keep accurate records and reduce losses in my uniform programs. When I control shrinkage, I protect my profits and keep my uniform programs running smoothly.

GMROI

Gross Margin Return on Investment (GMROI) measures how much profit I make from every dollar I spend on uniforms. I use this metric to see if my uniform programs are making money or just tying up resources. A high GMROI means I am selling uniforms quickly and at a good margin. If my GMROI drops, I know I need to review my pricing, ordering, or sales strategies.

Inventory management software helps me track GMROI in real time. I can see which uniforms sell best and which ones sit on the shelf. This information lets me adjust my uniform programs to focus on the most profitable items. By tracking GMROI, I make sure every uniform program supports my business goals.

Tip: Real-time inventory tracking, combined with the right software, gives me the data I need to optimize every uniform program. I can respond quickly to changes, reduce losses, and keep my group store for uniforms running at peak efficiency.

Group Uniform Program Management

Managing a group uniform program means I must focus on supplier reliability, flexibility, and consistency. These factors shape the uniform procurement process and help me deliver uniforms that meet every group’s needs. I rely on strong supplier relationship management to keep the program running smoothly and support team branding strategies.

Supplier Reliability

Supplier reliability is the backbone of any successful uniform program. I always evaluate suppliers based on their ability to fulfill orders, respond quickly, and maintain high standards. Reliable suppliers help me keep the uniform procurement process efficient and support group purchasing goals.

Fulfillment

I assess each supplier’s production capacity to handle large volume orders. I check if they use modern technology and innovation to improve efficiency. Sustainability initiatives also matter to me because they show a commitment to responsible procurement. I look for suppliers who deliver uniforms on time and maintain product quality. The table below highlights key factors I consider:

Factor | Leírás |

|---|---|

Timely Delivery | Ensures that the supplier can meet deadlines and maintain production flow. |

Product Quality | Reflects the standards of the uniforms produced, crucial for customer satisfaction. |

Order Accuracy | Indicates the supplier’s ability to fulfill orders correctly, reducing errors. |

Industry Certifications | Certifications like ISO 9001 demonstrate a commitment to quality management. |

Reliable suppliers help me maintain consistent product quality and timely delivery. This supports the group uniform program and keeps employees looking professional.

Responsiveness

Responsiveness is vital in supplier relationship management. I value suppliers who communicate clearly and solve problems quickly. I review their service level agreements and inventory management systems to ensure they can handle customization and branding requests. Financial stability also matters because it shows they can withstand market changes and deliver uniforms without interruption.

Note: Reliable suppliers with strong communication skills make the uniform procurement process smoother and help me adapt to changing group needs.

Rugalmasság

Flexibility in uniform program management allows me to respond to rush orders and design changes. I need suppliers who can adjust quickly when purchasing needs shift or when a group requests new branding elements.

Rush Orders

I verify each supplier’s track record for on-time deliveries and their ability to handle rush orders. I negotiate scalable minimum order quantities (MOQs) and tiered pricing to match volume forecasting. Sometimes, I request partial shipments to meet urgent group purchasing needs. The table below shows how I address common issues:

Issue | Solution |

|---|---|

Inflexible MOQs and pricing | Negotiate scalable MOQs, tiered pricing, and flexible reorder points. Pro tip: negotiate partial shipments or split shipments to match demand patterns. |

Design Changes

Design changes are common in group uniform programs. I work with suppliers who can adapt to new customization and branding requirements. I validate their capacity with fixed production calendars and output per shift. I build a safety buffer for peak periods and stagger orders across suppliers to balance risk. This approach keeps the uniform program efficient and scalable.

A flexible uniform program helps me save costs and maintain brand consistency. I can adapt to seasonal changes or role-specific needs, which improves customer satisfaction and supports program scalability.

Consistency

Consistency in uniform production is essential for branding and customer loyalty. I monitor batch uniformity and defect rates to ensure every group receives high-quality uniforms.

Batch Uniformity

I track batch uniformity by reviewing production reports and inspecting uniforms for consistent colors, logos, and styles. Consistent uniforms reinforce branding and help employees feel part of the group. The table below shows industry averages for batch failure rates:

Facility Size | Average Batch Failure Rate | Total Failure Rate |

|---|---|---|

>1,000-L scale | 1 every 40.6 weeks | 7.6% |

<1,000-L scale | 1 every 40.6 weeks | 6.6% |

Defect Rate

I aim for a defect rate below 1,000 parts per million (PPM), which means 99.9% of uniforms meet quality standards. This high level of consistency supports branding and builds trust with every group. Customers expect the same quality every time they purchase uniforms, which increases loyalty and supports program growth.

Tip: Consistent, high-quality uniforms strengthen branding and make group uniform programs more successful. Customers know what to expect, which helps me build lasting relationships and improve purchasing efficiency.

Group Store for Uniforms Performance

Sales per Square Foot

When I evaluate the performance of a group store for uniforms, I always start with sales per square foot. This metric shows how well I use the available space to generate revenue from uniform sales. I compare my results to other retail sectors to see if my group store for uniforms meets industry standards. For example, convenience stores average about $330 per square foot, while general retail stores reach $325 per square foot. Grocery stores often perform even better, averaging $500 per square foot. I use the table below to compare these numbers:

Retail Sector | Average Sales per Square Foot |

|---|---|

Restaurant (Full-Service) | Over $150/sqft |

Restaurant (Quick-Service) | Above $200/sqft |

General Retail | $325/sqft |

Convenience Store | Approximately $330/sqft |

Grocery Store | Average of $500/sqft |

Luxury Brands | Higher than average |

Big Box Stores | Higher than average |

Membership Locations (e.g., Costco) | Up to $1000/sqft |

I track sales per square foot in my group store for uniforms to measure efficiency. If my numbers fall below the average, I review my uniform display and stocking process. I adjust the layout to highlight popular uniforms and improve the flow for each group. This process helps me maximize revenue and make better use of every square foot.

Average Market Basket Size

Average market basket size tells me how many uniforms or related items each group buys in a single transaction. I use this metric to understand customer behavior in my group store for uniforms. When I see a higher average basket size, I know my uniform programs and promotions work well. I often bundle uniforms with accessories or offer discounts for bulk purchases. This strategy encourages groups to buy more uniforms in one visit.

To increase the average market basket size, I train my team to suggest additional uniforms or related products. I also use data from my uniform management system to spot trends. If I notice that certain uniforms sell well together, I create special offers for those combinations. This approach boosts efficiency and supports the goals of my uniform program.

Tip: Tracking average market basket size helps me design better promotions and improve the shopping experience for every group.

Sales Revenue

Sales revenue is the total amount of money my group store for uniforms earns from selling uniforms. I monitor this metric daily to see how my uniform programs perform. High sales revenue means my group store for uniforms attracts many groups and meets their needs. I break down revenue by uniform type, group, and program to find the most profitable areas.

I use sales revenue data to guide my inventory management process. If I see strong sales for certain uniforms, I increase stock for those items. If revenue drops, I review my marketing and adjust my uniform program. This process keeps my group store for uniforms competitive and efficient.

I believe that focusing on these three metrics—sales per square foot, average market basket size, and sales revenue—gives me a clear picture of my group store for uniforms’ performance. I use this information to refine my uniform programs, improve efficiency, and deliver the best results for every group.

Sales Growth

Sales growth stands as a key indicator of success for any group store for uniforms. I always track this metric to see how well my store adapts to changing customer needs. When I see steady growth, I know my uniform program meets expectations and attracts new groups. I use several strategies to drive sales growth and keep my group store for uniforms ahead of the competition.

I start by merchandising my store to influence customer behavior. I place high-margin uniform items in areas where customers will notice them first. This approach helps me educate customers about unique uniform options and encourages them to try something new. I rotate displays often to keep the store fresh and highlight seasonal uniforms. When I showcase new arrivals or limited-edition uniforms, I create excitement and boost program engagement.

Offering value-added services sets my group store for uniforms apart from larger retailers. I provide embroidery and alterations for uniforms, which adds a personal touch. These services make my uniform program more attractive to groups who want custom branding or a perfect fit. Customers appreciate the convenience and return for future uniform needs. I see that loyalty grows when I offer services that mass retailers cannot match.

Building relationships with local businesses forms the foundation of my recurring revenue. I reach out to schools, offices, and community organizations to introduce my uniform programs. I offer special pricing and tailored services for groups that commit to regular uniform purchases. This approach creates a loyal customer base and ensures steady sales growth for my group store for uniforms. I track each program’s performance and adjust my offers to meet the needs of every group.

I use data from my uniform management system to monitor trends and identify growth opportunities. I analyze which uniforms sell best and which programs generate the most revenue. When I spot a successful program, I expand it to other groups or locations. I also review customer feedback to improve my uniform selection and services.

Here are some effective strategies I use to increase sales growth in my group store for uniforms:

Merchandise the store to highlight high-margin uniform items

Offer embroidery and alterations for uniforms

Build relationships with local businesses for recurring group uniform sales

Tip: Consistent sales growth in a group store for uniforms depends on understanding customer needs, offering unique services, and building strong group relationships. I always adapt my uniform program to stay ahead in a competitive market.

I believe that tracking sales growth helps me make better decisions about inventory, marketing, and program expansion. When I see positive trends, I invest more in successful uniform programs and explore new opportunities for my group store for uniforms.

Customer Metrics

When I manage a uniform program for a group, I always track customer metrics to improve long-term success. These metrics help me understand how much it costs to attract a new customer, how much value each customer brings, and how satisfied customers feel with my uniforms and service. By focusing on customer metrics, I make better decisions for my uniform management process and boost efficiency across every group uniform program.

Customer Acquisition Cost

Customer acquisition cost (CAC) shows me how much I spend to gain a new customer for my uniform program. I include marketing, sales, and onboarding expenses in this calculation. When I keep CAC low, I improve efficiency and make my uniform management process more profitable. I compare CAC across different group uniform programs to see which strategies work best. If I notice that one group requires more resources to attract, I adjust my approach to save money and time.

I track CAC for each group uniform program.

I review marketing and sales expenses for uniforms.

I use CAC data to refine my uniform management process.

Customer Lifetime Value

Customer lifetime value (CLV) tells me how much revenue I can expect from a customer over the entire relationship. I use CLV to measure the long-term impact of my uniform programs. When CLV is high, I know my uniforms and service keep customers coming back. I focus on building strong relationships with each group to increase CLV. I offer personalized uniform options and efficient management to encourage repeat purchases.

I calculate CLV for every group uniform program.

I analyze uniform sales history for each customer.

I use CLV to guide my uniform management and retention strategies.

The ratio of CLV to CAC is a key indicator of financial health in my uniform programs. For example, if I spend $100 to acquire a customer and that customer generates $500 in revenue from uniforms, the 5:1 ratio means my program earns $400 in profit. I aim for a high CLV:CAC ratio to ensure my group uniform programs remain efficient and profitable.

Metric | Leírás | Fontosság |

|---|---|---|

CAC | Cost associated with acquiring a new customer. | Measures effectiveness of acquisition strategies. |

CLV | Total revenue expected from a customer throughout their lifecycle. | Represents long-term value of customer relationships. |

Ratio | CLV to CAC ratio indicates financial health. | A higher ratio suggests better profitability from customer acquisition. |

Customer Satisfaction

Customer satisfaction is vital for every uniform program I manage. I collect feedback from each group to learn how they feel about my uniforms and service. High satisfaction leads to repeat business and strong relationships. I use surveys, reviews, and direct conversations to measure satisfaction. When I see positive feedback, I know my uniform management process works well. If I find areas for improvement, I act quickly to fix issues and maintain efficiency.

Tip: Satisfied customers become loyal advocates for my uniform programs. They recommend my uniforms to other groups and help my business grow.

I believe that tracking customer metrics is essential for every group uniform program. These metrics guide my decisions, improve efficiency, and support long-term growth in uniform management.

I always track every uniform metric to improve my group uniform program. Uniform quality, production speed, and cost shape my approach. I use real-time inventory tracking for uniforms to keep my group store for uniforms efficient. Uniform management tools help me spot trends and make smart decisions. I review my group uniform program often. Uniforms must meet group needs, so I adjust my program as needed. Uniform tracking and group feedback guide my uniform program. Uniform management leads to better uniforms and stronger group results.

Regular review of your uniform program ensures every group gets the best uniforms.

GYIK

What is the most important metric for bulk uniform production?

I always focus on uniform quality first. Durable fabric and strong stitching help uniforms last longer. High quality reduces returns and boosts customer satisfaction.

How do I track inventory for group uniform programs?

I use inventory management software. Real-time tracking lets me see stock levels instantly. This helps me avoid shortages and overstocking.

How can I reduce order errors in bulk uniform production?

I double-check every order before production. I use a checklist for sizes, colors, and styles. Order management software helps me prevent mistakes.

What should I look for in a reliable supplier?

I choose suppliers who deliver on time and maintain high product quality. I check for industry certifications and strong communication skills.

How do I handle rush orders for uniforms?

I work with flexible suppliers who can adjust quickly. I negotiate partial shipments and scalable minimum order quantities to meet urgent needs.

Why is customer feedback important in uniform programs?

Customer feedback shows me what works and what needs improvement. Positive reviews build trust. I use feedback to refine my uniform program.

What is GMROI and why does it matter?

GMROI stands for Gross Margin Return on Investment. I use it to measure profit from every dollar spent on uniforms. High GMROI means my program is efficient.

How do I keep uniform costs low without sacrificing quality?

I compare suppliers and choose materials that balance durability and price. I optimize labor costs by training my team and streamlining production.